Delivering the right information to the right people at the right time is crucial for the success of a business, no matter the size. However, it’s not always possible to achieve this due to (1) not having access to the right information or (2) having access to inaccurate or incomplete information.

This can be caused by manual data management efforts. One file here, another there, and more others scattered in a wide array of sources often leads to information that lives in silos.As you can imagine, and probably experienced once or many times before, it’s hard to track, fix, and manage heavy chunks of data that live in multiple areas. This is where gaps for miscommunication occur, both internally and to external partners.

Ultimately, the upstream and downstream portions of the supply chain are affected. It’s a domino effect that can only be solved by unified and automated data management.

In fact, according to this, data integration is one of the top three technologies that organizations are planning to automate by the end of this year. Gartner even suggests that hyperautomation is accelerating so much that by the time we wrap up 2025, more than 20% of products will be manufactured, packed, shipped, and delivered without anyone touching them.

As you can see, automation saves time, increases productivity, and efficiency. It’s also safe to say that these benefits are possible because the communication flow is seamless. That’s what a product information management software helps you achieve. Let’s look at the top ways a PIM tool improves internal communication and upstream data sharing.

Unifies data

The growing appetite for a product content management tool comes from the realization that centralized data is easier to manage. It enables businesses to standardize complex product data and knocks down data silos. So, instead of jumping around from one file to the next (which is time consuming and tedious), you’re now looking at an overview of all kinds of product data from a single location. This includes SKUs, descriptions, product weight, color, and material, etc. to digital assets and every data point that moves between your organization, suppliers, manufacturers, and end-customers.

When data lives in a unified environment, you’re able to spot missing elements, inconsistencies, and inaccuracies that you can easily and quickly fix. In the end, you’re able to ensure data quality control.

Fosters internal collaboration

Data management is not a one-person job, at least it shouldn’t be.You have to consider that each department in your organization uses data for different purposes. So, it’s a no-brainer that each and every one should have access to the same data to be on the same page. Having access to the same data ensures that everyone executes their functions without making mistakes that can affect other departments. In addition to that, access to the same data eliminates internal miscommunication.

For instance, putting the right product material type in one data management system keeps the information up-to-date and accurate. That way you, you know that no one will accidentally stumble upon an old Excel spreadsheet with the wrong details. So, when teams engage with each other, they have confidence in the accuracy and quality of the data they’re sharing. This improves the way employees work together.

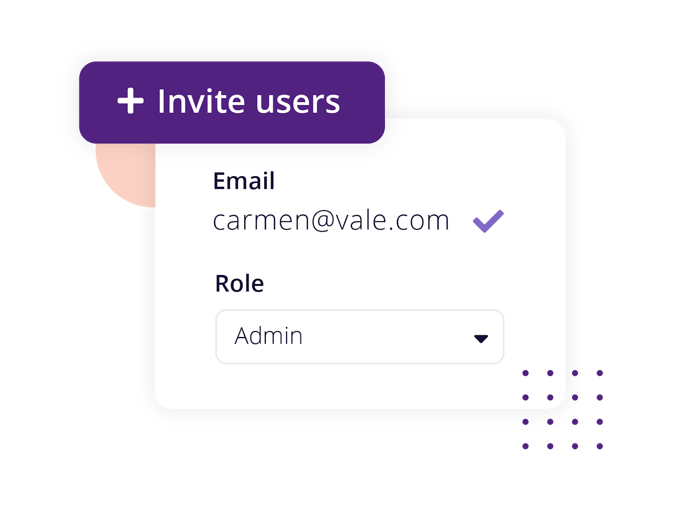

And, with a product content management tool like Plytix that allows unlimited users at no extra cost, you’re guaranteed a great collaboration effort as none of your team members will have to wait for user permissions to perform their tasks. Each person in every department can enjoy a seamless experience from a role and task-based product database, doing their part to contribute toward a common goal.

Encourages real-time upstream data sharing

All stakeholders involved in the upstream portion of the supply chain are working together to achieve the goal of delivering the right final products. These stakeholders include your internal team, raw material suppliers, vendors, or even manufacturers. There’s a wide range of data which needs to be shared between each other to fulfill the end goal. A single mistake in the data-sharing chain can lead to delays in the manufacturing process or the development of products in incorrect formats.

Using the product material example again, if your company shares the wrong material information for product manufacturing, the product will have to be scrapped and redone all over again. That’s a cost to the company. But here’s what happens when you implement a PIM that centralizes all product data, including inventory related information such as product materials, you’re able to:

- Easily spot and fix data errors quickly

- Make data-driven decisions

- Share real-time data with all stakeholders

In the end, everyone involved will be on the right track and ensure continuity throughout the product development phase. Not to mention that you’ll have improved relationships with your suppliers and other parties involved.

Eliminate internal and external miscommunication with Plytix

With all of the information above, it’s clear that a PIM tool is a necessary technology to invest in. It’s not ONLY a master product catalog management tool that helps you better manage your ecommerce product catalog, but it can also significantly improve the quality of your internal and external communication capabilities.

We don’t know a single company that wouldn’t enjoy that benefit. So, why not book a demo with us to learn more about how Plytix can help you improve your communication. While you wait for the meeting to take place, you can download and read this free Ultimate PIM Buyer’s Guide to gain more insights on how to shop around for a suitable product information software!